build workbench

“+10,000 Step By Step Plans …even if you don’t have a large workshop or expensive tools!“ Yes, Get Access To 12,000 shed Plans! 👈

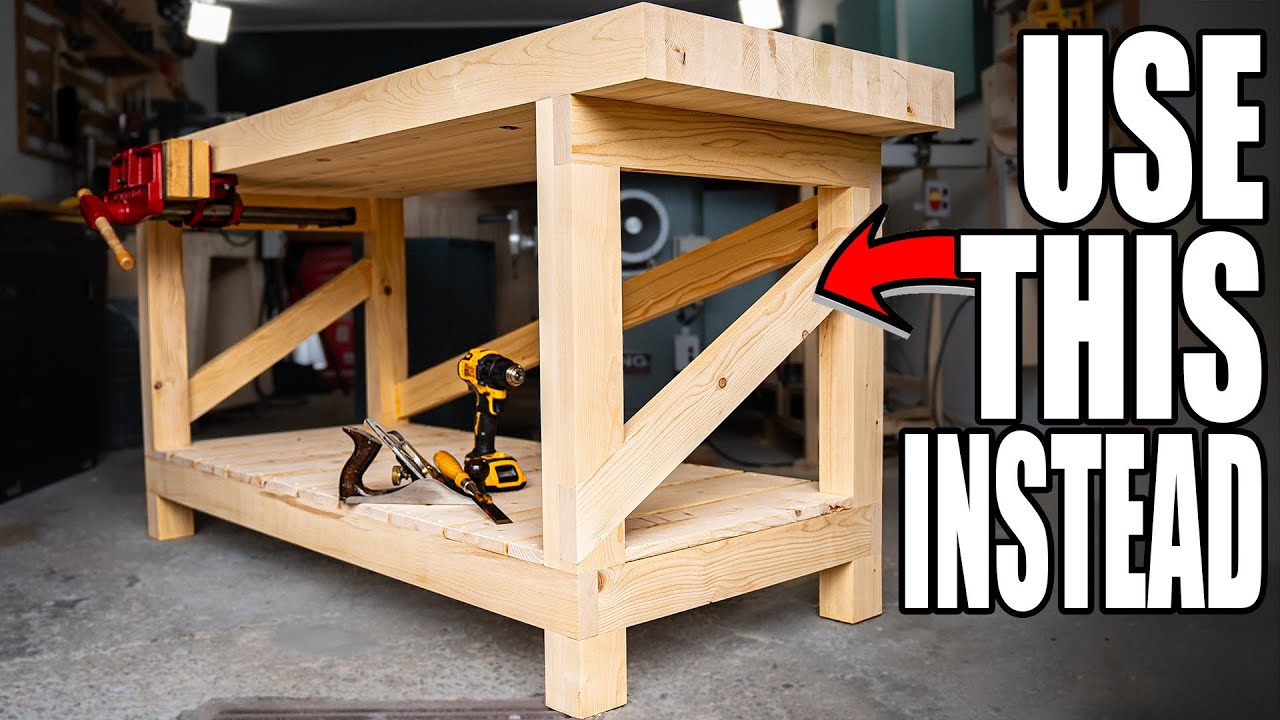

I’m going to show you how to build my third workbench design that’s super sturdy costs under 200 and I’ll show you how to avoid all the mistakes that I made when making my first workbench including why you shouldn’t use two by fours three work three bench Tokyo Drift [Music] eights for almost the entire build but they don’t need to be this wide so I’m going to rip them right down the middle yep I’m buying two by eights just to cut them into two by fours strange yes I am strange but it’s not strange that I’m cutting them down because I want the top of my workbench to remain as flat as possible over time which is one of the biggest issues I had with my old workbench you can see that the top cupped about a quarter of an inch and trying to work on it nearly send me into anaphylactic shock now I’ll get back to the whole 2×4 thing in a minute but the first step to success is to make sure These are nice and flat foreign if you don’t have a planer don’t worry I’ll show you how to laminate a bench top so that it comes out nice and flat even without a planer but what you should go out and buy is a cheap Dollar Store paint roller because nothing screams quality like a pro painter 1.75 paint roller but what this globetrotting reminder of excessive trade route emissions will allow us to do is spread the glue out super fast so that it doesn’t start drying too quickly and cause me to go into the hissy fit of the century and the great thing is is that I can just throw this away when I’m done with it I’m not a part of the problem you are oh I grabbed some extra two by material that’s nice and straight and I’ll be using them as clamping calls by cinching them across the top as I squeeze the boards together this will take out any misalignment I’m only doing the top in sections no wider than my planer can handle because even with the calls I can send the result back through the planer for a smoother result thank you [Music] nothing is more accessible than your local home repo so let me show you what to look out for when buying the lumber for your workbench might look at the stack the stack two by fours first and think whoa those are a good deal but I always avoid them see most of these have this Bullseye looking thing in the end grain called the pith but why is that a bad thing well the pith is the center of the tree and because of the way that wood expands and contracts as moisture in the air changes it is the least stable part and including it in your project can really mess it up where am I this is a weird edit whoa back at the shop you can see here that inexperienced Scott used all two by fours for the workbench top most of them have the pith in them so there are all kinds of delaminations and gaps in the top because the wood is warping as it takes in and releases moisture throughout the year so if you see a 2×4 with a pith in it avoid it this is one Bullseye you do not want but even without the pith 2x4s tend to be a little wetter because they are sold and produced a lot faster than larger dimensional Lumber can I ask you a really weird question how much faster do you sell two by fours and two by Eights yes right on thanks man the beauty of something larger like a 2×8 is that I can more easily find one without the pith then I can rip it in half and end up with two boards that are going to be more stable and dry over time which will result in a flatter workbench which is always gooder now that the SE are cleaned up with the planer it’s time to glue them both together and this time although I’m only dealing with the one glue joint the stakes are a little higher because there is no way I’m fitting this whole thing through the planer after it’s dry so it needs to be perfectly lined up I drilled several holes for dowels along the sides so that the two halves of the top will stay aligned as I’m gluing them up but I am still adding calls again to make sure that the entire top ends up as flat as possible when the glue dries belt and suspenders Maybe [Music] the height of the legs are going to determine the height of the bench top I’m six foot and I prefer it to be 36 inches high if you don’t know what height you prefer you can add or subtract a half inch for the workbench height for every inch higher or lower you are compared to me so for instance if you’re five foot eight tall then make a 34 inch high bench then just subtract the thickness of the top which in my case is three inches and that’s your leg height see leg day is easy for the roughly guesstimated 40 percent of you that have seen my other workbench build you’ve probably been screaming at your screens wondering what about this beautiful Ash workbench that I made last year relax it’s not going anywhere because it’s still the bench of my dreams but this build is not for the faint of heart so I wanted to make a workbench that’s easier to make for those who haven’t yet abandoned their social lives for woodworking and metamorphosed into a crusty old hermit it’s also one of my best-selling set of build plans so naturally I’m turning into the capitalist I was born to become so for my new construction Lumber bends there are plans for sale on my website and the link is in the description I am waiting for my dump truck full of money now that we’ve figured out the leg height the joinery that we’ll be using to connect the legs to the aprons is going to be half laps and if you’ve seen my joinery test video you’ll know that the half lap is actually stronger than a mortise and Tenon in the scenario that I tested it in and it’s a super easy joint to make too instead of cutting the Laps on the table saw you could glue this leg up in a way to naturally leave the half laps in place but in my experience this doesn’t turn out as accurate as doing it on the table saw wood besides that would only work for these joints on the sides of the bench and we still have to do more of these to connect the sides together [Music] foreign [Music] like many children from a broken household one big issue that this workbench experienced was a lack of stability as you can see I thought I did the right thing by adding this big 2 by 10 stretcher below but clearly it wasn’t enough and now I know a much easier way to prevent this racking from happening I’m going to lap in a few diagonal braces around the entire workbench and let me show you why using my delightfully half-assed stick model when you squish or pull a square from opposite Corners the distance between these two corners gets closer or farther apart now by diagonally bracing it hold please by diagonally bracing it it prevents the Square from becoming a diamond because you can’t squish or pull that diagonal brace woodworker could use a track saw for this but we can use a circular saw in the same way the exact angle doesn’t matter too much I’m just going to lay my diagonal brace so that it goes from corner to corner without intersecting the top and bottom stretchers clamp a straight edge down so you can cut the inside of the bottom line [Music] now the seemingly smart thing to do when B2 offset our straight edge by the width of our brace piece no you must resist this urge because this doesn’t account for the width of our circular saw blade and if you did this you would end up with too loose of a fit with the half laps so we need to offset it by the width of the blade first I’m going to double side tape the brace temporarily up against our straight edge now I can take off our first straight edge I’m going to use a 3 32 inch drill bit to simulate the thickness of my circular saw blade and if you have two of them even better what I’m going to do is take the straight edge and offset it from our taped down piece right here just like that and then we can clamp it back down now I can unstick our brace remove our drill bits and place the brace piece straight up against the straight edge without the drill bits and clamp the brace into place now we can go ahead and make another pass with the circular saw to establish the top of our half lap that looks pretty good now it can take off the brace and hog out the rest of the waist with our circular saw [Music] thank you now that both sides are done I can join them together and I’m going to use more half flaps now I’m going to glue them together so they’ll never be able to come apart but if you want to break the bench down easily you might consider just screwing them together although it might not be as rigid in the end now a way to make life easier right now is to clamp both sides together perfectly lined up so that I can cut the laps that connect the long stretchers to both sides at the same time thank you construction Lumber can be super soft but depending on where you live it might be better or worse but the stuff that’s available to me is soft enough that I can Dent it with my fingernail so shouldn’t a workbench be like super strong and super hard well yeah but also no yes we’re creating a bench with a super Stout top and a sturdy base and it’s gonna be Dwayne The Rock Johnson solid but sometimes a soft wood top can save your butt let’s say I’m working on a project it’ll usually be made out of hardwood because you know I’m super classy as I’m doing my thing on a work piece I might you know drop it on my bench because I’m classy and clumsy wouldn’t you rather your bench take a dent rather than your work piece if it’s something small yeah I can probably fix it but it could also mean that I need to remake the whole part if it’s bad enough and I’m not about that [Music] if you don’t have a jointer don’t worry because I didn’t use my jointer at all on this project and as you can see the top came out really nice without any gaps and all I did was run it through my planer on each side now if you don’t have a planer you can also still build this workbench but you might end up with a little Gap here and there in the top laminations one big thing that’ll help you out is applying a finish to your bench top when you get drips of glue on the top as you’re working you’re going to want to remove them easily and if you put a couple of coats of a water or oil-based Poly on it the glue will just uh pop off like the young and say be sure to apply finish to both the top of the top and the bottom of the top or else the top might end up cupping one more reason why my old bench top worked so much is because that I didn’t leave any room for the wood to expand and contract as it took up and released moisture throughout the years even worse I think the wood was very wet when I made the top which I subsequently lag bolted directly to the base it tried to shrink but the bolts were partially preventing it from shrinking so the top did the only thing it could do and unintentionally turned into Tony Hawk’s half pipe to prevent this from happening again in my new bench I’m drilling oversized half inch holes through the top stretchers but I’m only using quarter inch lag screws so there would be plenty of room for the top to expand and contract I’m also using a quarter inch washer and a half inch washer stacked here to make sure that the bolt doesn’t get any funny ideas thank you [Music] the base is on its legs for the first time and it’s looking real good and it’s almost done but I think I want to add another brace to stiffen it up because it’s just slightly racking you probably can’t see it on screen but I think I could use one more the great thing about this bench is that it doesn’t cost a whole lot to make I used 9 12 foot two by eights that were 15.28 cents each I used four eight foot one by sixes which you’ll see soon that were 11.98 each and some lag screws and glue which brings the total to just shy of two hundred dollars to get you up and running but there are a few things you might want to add to this bench to make it work smarter for you [Music] a traditional front Vise is still a great idea even if you don’t plan on doing traditional woodworking because it’s very versatile and can hold a work piece in basically any orientation these styles of cast iron front vices are very easy to install with four lag screws however I made a big mistake when installing it on my old workbench even though I had a vise mounted on my old bench I forgot about one of its best features which meant I couldn’t hold a board flat down to the workbench and it was such an easy fix but because I’m lazy I didn’t do anything about it so I just found myself using clamps to secure a work piece flat on the bench by drilling a row of holes in front of the Vise I can use the pop-up dog in the vice and one more dog in any of these holes to securely hold a panel or piece of plywood flat against the bench top and I can work on it without it moving around it’s such an easy thing to do and now I don’t have to use clamps to hold it down flat because using clamps is time consuming kind of annoying and they just get in the way this is the vice for my current workbench I’m not gonna go buy a new Vise for this bench because for what I’m using this bench for I don’t really need advice but be sure to mount it such that the top of the Vise is flush with the top of the workbench because if you don’t as you can see here this dog barely reaches this panel right here so that’s a bit of a problem so make sure to create a recess underneath the top so that you can achieve that and I’ll leave a bunch of links down below to some vices that I like so you can buy one for your workbench now a lot of people use t-track on their workbenches for the same purpose but I’m not a big fan of them because I find that the accessories for them are a little more limited they’re more time consuming to install and they always tend to get filled with Gunk and sawdust but most importantly there is one big issue with them being installed on a solid wood top like this when the top wants to expand and contract as it changes in moisture content throughout the year the t-track that’s screwed across the top leaning across the grain is not going to want to move which like I said before is gonna make the top cup and that alone is a huge reason to avoid it [Music] thank you there’s always a big opportunity for lots of storage underneath a workbench and for this one you have a few options and the simplest one to get you up and running fast is to screw down a bunch of slats between the bottom stretchers now to take it up a notch you could make a simple cabinet out of some plywood with some simple shelving to expand the space a bit more to make it even better instead of shells you could outfit it with some drawers both of these options would be sweet but are a bit more involved and outside the scope of my build if you go back and watch the video on my other workbench you can see how I made that cabinet another thing you can do to make a workbench work better for you is to install some heavy duty leveling feet because floors are notoriously undulatory it’s a word a thesaurus told me so but when you’re wrapped up working at your workbench and you wish to wheel it to Once forth to your wall without the wheels and I can’t finish that alliteration you can install some flip down casters on your workbench to make moving it around easier I installed them on my current workbench but I’ve only used them once when I moved otherwise it just kind of stays where I like it but some of you might not be able to keep their bench in the same spot so they are a good idea for some [Music] foreign [Music] this bench is freaking fantastic and these plans are also freaking fantastic so go check them out and my other plans on my website www.scottwash.com or dot CA some stupid web developer snatched up those domains I’m not salty at all respond to your email Scott Walsh …

“+10,000 Step By Step Plans …even if you don’t have a large workshop or expensive tools!“ Download Today! 👈